[ad_1]

Porsche’s first sports activities vehicles had aluminum physique panels, but it surely was nature’s personal light-weight materials that made their iconic form potential.

The Porsche 356 had bodywork that the place the panels have been hammered and hand rolled into form, and a picket body mannequin was used to make sure every thing lined up.

That body nonetheless exists, and is in comparatively good situation. It is on the Porsche Automuseum in Gmünd, Austria, the place the first Porsche production cars have been accomplished earlier than manufacturing moved to Stuttgart, Germany.

The body is typically referred to as Holzklopfmodell, which is German for « hammered picket body, » however the body itself wasn’t hammered. Relatively, it served as a mannequin the manufacturing unit employees used for shaping and becoming of the aluminum physique panels. It was a time-consuming course of that generally required a number of makes an attempt to get a door or fender to completely match the body, which was the precise form of a 356 physique. The method took not less than 90 hours, based on Porsche.

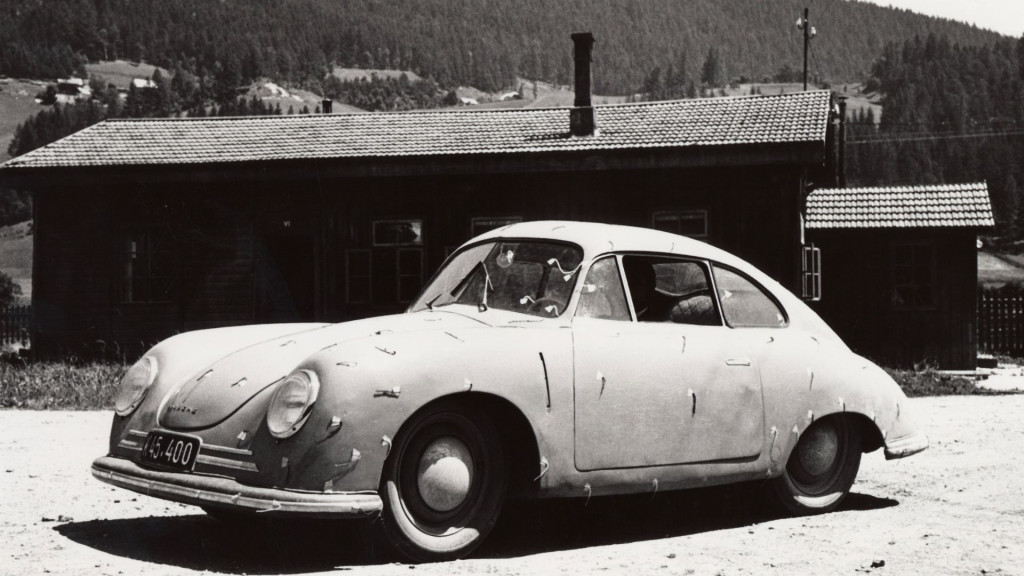

Porsche 356/2 coupe manufactured in Gmünd, Austria

Handmade bodywork was primarily a function of the earliest Austrian-built Porsches. Beginning in 1948, Porsche constructed 52 vehicles in Gmünd, together with 44 coupes and eight convertibles, plus between eight and 10 super light (SL) bodies that have been accomplished by Porsche’s racing division in Stuttgart between 1951 and 1952.

When manufacturing shifted to Germany in 1949, Porsche switched to metal our bodies and mechanized manufacturing processes, leaving hand-formed aluminum for specials just like the 16 light-weight 356 America Roadsters. A brand new picket body ultimately changed the unique.

As a result of metal is far tougher than aluminum, Porsche began utilizing presses to fabricate physique panels, which additionally allowed it to supply vehicles at a sooner fee. At this time, the 356 wooden body stays as a reminder of the automaker’s early days.

[ad_2]