[ad_1]

Sponsored put up introduced on aBlogtoWatch for advertiser

Eight years could make for loads of alternatives within the historically slow-paced watch trade. In that point, Bulgari cast a path that nobody might even dream about following, setting eight world information in ultra-thin mechanical watchmaking. It was in late 2015 that aBlogtoWatch final got down to clarify the capabilities of Bulgari as a vertically built-in watchmaker, at a cut-off date when a lot of Bulgari’s ultra-thin journey nonetheless lay forward. We discovered what the complete integration of watch manufacturing amenities means — the place the circumstances, dials, bracelets, and actions — and most all motion elements — are produced in-house at actually proprietary manufactures for almost all of Bulgari watches. The previous couple of years have confirmed that such integration can provide the Italian-Swiss model the potential to effectively develop and produce many distinctive and specialised timepieces within the close to future. Nonetheless, even with all that out within the open, no person might have foretold the outstanding evolution Bulgari would put itself and its manufactures by way of, and that’s what we traveled as soon as once more to Switzerland to find.

On the time, within the mid-teens, the Finissimo line of record-thin watches was nonetheless very a lot in its infancy. Immediately, it has set quite a few world information in ultra-thin mechanical watchmaking and expanded to supply many extra extremely spectacular fashions moreover these eight references. Breaking a report is an admirable factor, however setting over half a dozen exhibits not solely intent, however lasting capability to engineer, develop, and understand watches on a unique stage. This lasting capability couldn’t have come from wherever however inside. Bulgari has been quietly engaged on restructuring its amenities to help its journey not solely in the direction of new information but in addition to higher flexibility in order that it could possibly provide daring new watches and unleash creativity extra incessantly. This necessitated leaning on the know-how of its craftspeople in a singular vogue: This time, some eight years later, we returned to Bulgari’s watch manufacturing amenities in Switzerland to find its actually distinctive method to higher watchmaking.

This time, some eight years later, we returned to Bulgari’s watch manufacturing amenities in Switzerland to find its actually distinctive method to higher watchmaking.

There are three major websites the place Bulgari watches are made at this time. Bulgari Horlogerie, the headquarters of Bulgari watches, is in Neuchâtel, the French-speaking capital of the Swiss canton Neuchâtel that lies on the northern shore of picturesque Lake Neuchâtel. This large HQ constructing with a view of the lake is accountable not just for design and advertising but in addition for among the most vital steps in making a watch, particularly emboîtage i.e. casing-up, becoming the straps or bracelet, ultimate high quality management, in addition to the operation of logistics and after-sales servicing. We’ll return right here on the finish of this text, after all, as soon as we get to those ultimate phases of manufacturing a Bulgari timepiece.

Bulgari Manufacture De Haute Horlogerie is in Le Sentier, rooted proper on the coronary heart of Watch Valley — as a result of sure, there’s a Watch Valley within the “watch nation” that’s Switzerland. Bulgari isn’t shy to confess that it needed to be right here, on the coronary heart of all of it, if it needed entry to all of the expertise and know-how — Swiss craftspeople are but to develop a popularity for mobility, not even inside their motherland. It’s right here, in Le Sentier, that actions, together with lots of their tiniest and most delicate distinctive elements, are crafted and assembled. From the three-hand and date BVL 191 automated all the best way to the 923-component Grande Sonnerie Perpetual Calendar, in-house Bulgari actions are manufactured and assembled piece-by-piece by Bulgari Manufacture De Haute Horlogerie.

Bulgari Manufacture d’Habillage in Saignelégier the place dials, circumstances, and bracelets are made for Bulgari watches.

The ultimate and completely important ingredient of Bulgari’s absolutely built-in watchmaking capacities is Bulgari Manufacture d’Habillage in Saignelégier, one of the crucial prestigious and succesful producers of high-end watch circumstances and dials on the earth. It’s also right here that Bulgari has carried out probably the most significant developments over the past eight years by the unprecedented integration of its separate dial and case manufacturing amenities beneath one roof, right here in Saignelégier. Amongst these three websites, some 400 workers are centered on designing, engineering, producing, sub-assembling, and assembling the actions, circumstances, dials, and completed Bulgari watches.

Processes start with a design idea by Fabrizio Buonamassa (catch him discussing Bulgari watch design here), as he works with the engineers on the three amenities on the small print of how his sketches might be changed into a wearable, sturdy, lovely case, bracelet, dial, and motion. A core fact of the trendy Swiss luxurious watch trade is that neither Bulgari nor some other model might handle to create such a variety of various fashions from such all kinds of supplies with out direct entry to a proprietary manufacturing background. Prototyping one thing as apparently easy as a brand new dial or case design is commonly turned down by non-exclusive specialist suppliers as a result of they don’t are inclined to have the bandwidth to dedicate the effort and time this may require to please all their shoppers.

Cautious planning is necessitated for 2 major causes. The primary is to remain as shut as potential to the unique idea of the design group. As is true for the enduring merchandise of the automotive and client electronics trade, lots of an important and profitable luxurious watches come from inventive groups who assume outdoors the field. Considering outdoors the field on paper is already a trial of an organization’s capabilities, however turning a lofty thought right into a product that may be repeatedly crafted in a ravishing and environment friendly method is the place a brand new dimension of challenges actually opens up. Via limitless dedication and funding, Bulgari has acquired the groups with the required know-how and the equipment with the mandatory capabilities to help this transition from paper to steel.

Rooms with gigantic machines the dimensions of an SUV — and the price of many — are in operation in Saignelégier to show blocks of stainless-steel, titanium, 18k gold, and 950 platinum into Bulgari-styled circumstances and bracelets. In pursuit of thinness, many case elements the trade had found out way back, reminiscent of bezels, center circumstances, and casebacks, needed to be basically reengineered to have the ability to encapsulate the model’s ultra-thin actions and dials and to safeguard them with spectacular water resistance. Bulgari’s groups function and program all these mighty difficult and expensive machines and use bespoke instruments, seen within the third image within the gallery above, to securely maintain the assorted case and bracelet elements all through the machining steps.

One of many many desirable rooms right here in Saignelégier is the place the daunting process of case sprucing is carried out by Bulgari’s craftspeople. It’s darker than some other in any of the amenities, with solely the person’s working space being brightly lit. Whereas watchmakers assembling actions and their sub-assemblies are usually located on the high flooring of manufactures, permitting in as a lot daylight as potential for the brightest working environments, case and bracelet polishers choose a darkish room as a result of it completely minimizes distracting reflections on the workpiece. Simply above a purple protecting coating may be seen throughout choose phases of case ending — seen right here as alternating floor therapies are utilized by hand to the complicated angular construction of the Octo Finissimo case. Different fashions might need a sandblasted end, additionally utilized by hand, for a matt, industrial, fashionable aesthetic most frequently used on titanium.

Dials of the best precision and refinement at the moment are produced beneath the identical roof as circumstances. That is the results of a change that culminated in 2019 when Bulgari merged its La Chaux-de-Fonds-based dial manufacturing facility with the Saignelégier case manufacturing facility. The purpose? To experiment with one thing utterly new that might, once more, solely be an possibility for these with a completely built-in manufacturing background: To mix the assorted abilities and experience particular to dial and case manufacturing. As was the case with basic mobility, the identical restraint and conservatism maintain true when it to the assorted fields of experience: Craftspeople devoted to at least one area are well-known throughout the trade to have little to no need to bond with others from different fields.

It’s nothing private, only a logical intention to safeguard one’s personal traditions, rigorously developed skillsets, and know-how, and an comprehensible aversion to the potential introduction of confusion into any of those parts. These initiating this transformation at Bulgari had been after all nicely conscious of those variations — they’re as a lot an integral a part of their respective amenities as anybody else. They had been nonetheless intrigued by the thought of mixing these various kinds of information for they may see the underlying similarities. Circumstances and dials are extraordinarily delicate elements that may solely attain their ultimate kind and excellent high quality after receiving a variety of care and a focus from devoted craftspeople.

Extra importantly, at Bulgari, there all the time are new challenges to be overcome in dial and case manufacturing, because the design and engineering group retains pushing the boundaries of those fields. New floor therapies and but thinner executions on dials, circumstances with unprecedented angularity and complexity in an especially slender house — challenges like these have pressured Bulgari into new methods of problem-solving, because it might rely on nobody else however itself to work out the options. Because it seems, by merging the dial and case manufacturing amenities, sure abilities, dexterous strikes, and novel approaches might be carried out throughout these two hitherto strictly separate fields, yielding much-needed options in a well timed method, permitting Bulgari to remain true to the unique ideas it has dreamt up for its numerous watches and actions. The precise specifics of how these very totally different colleges of watchmaking have merged will after all stay a intently held secret for Bulgari, however this years-long technique of bringing amenities, machines, and, most vital, individuals, beneath one roof has given the manufacture a novel edge.

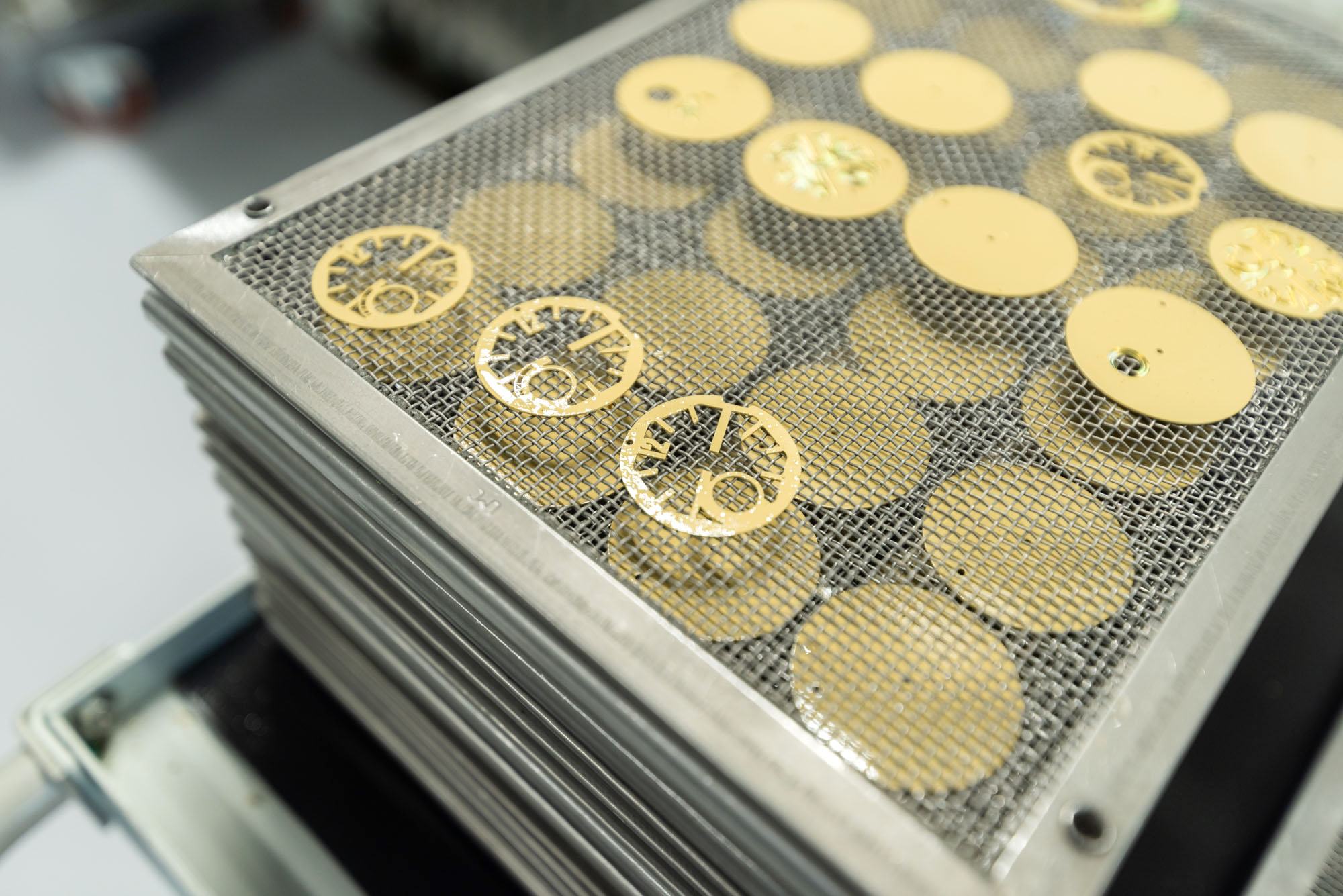

From milling, adorning, and soldering particular person hour markers by way of multi-layer pad printing to enameling, Bulgari’s dial manufacture actively makes use of its huge set of instruments and experience. Producing a dial is each bit as troublesome as it’s to make a frantically ticking motion, the tolerances are completely minuscule in a construction that’s simply of comparable complexity. A dial, even when painted solely by hand and fired in a kiln on a number of phases, must be completely even and extremely skinny, in any other case, the arms gained’t be capable to go over it. It’s also the element that’s rightfully known as the face of the watch, and the half the proprietor will doubtless spend probably the most time and scrutinizing, leaving no room in anyway for the slightest blemish or error.

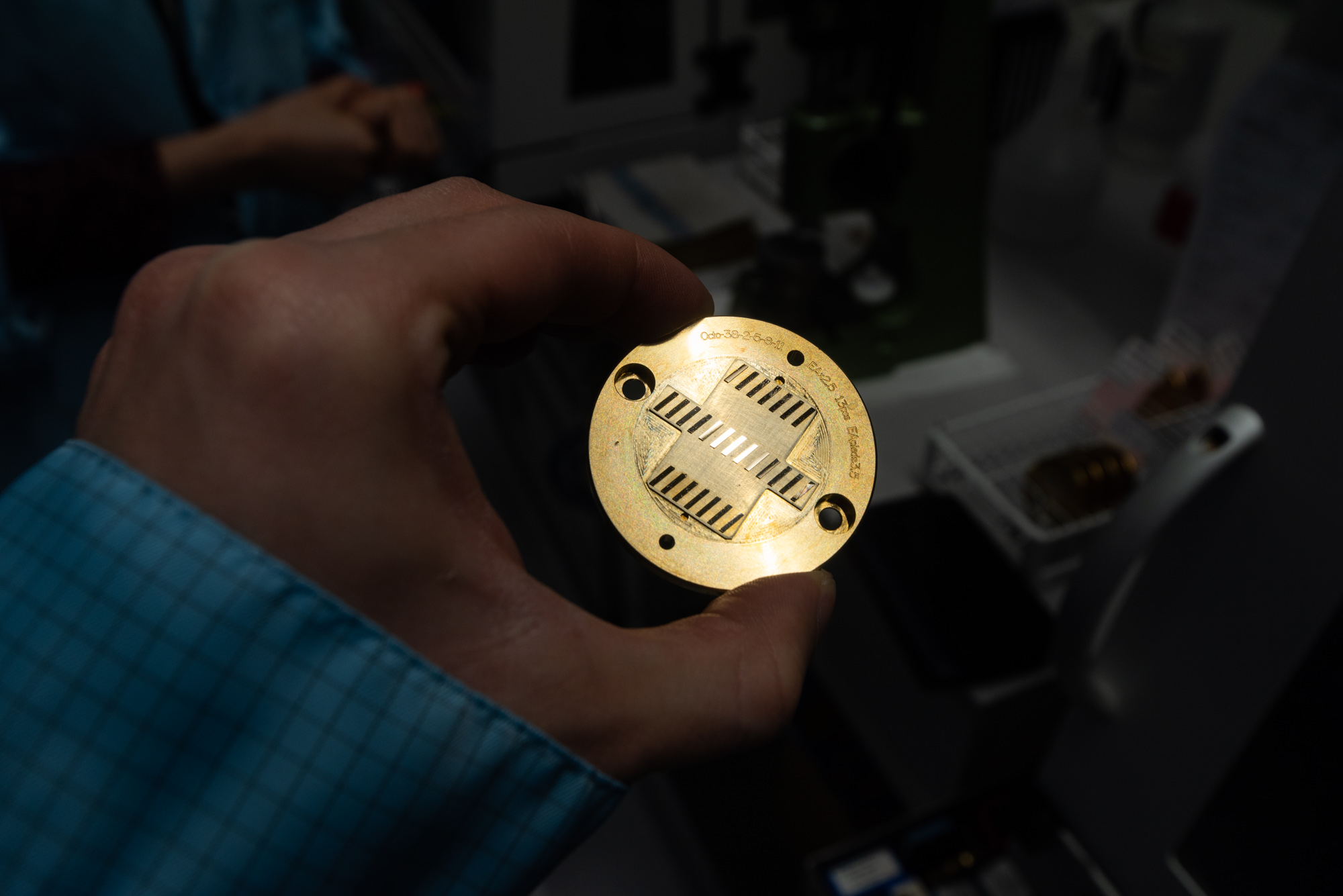

A real watchmaker will produce as lots of its motion components as potential, together with wheels, gears, and pinions — and that’s precisely what Bulgari performs in its Le Sentier facility, in The Watch Valley. Within the photos above, a freshly made element is being checked with an accuracy of 1/10,000th of a millimeter, or a tenth of a micron. It’s a uncommon have a look at the tolerances every a part of an ultra-thin motion has to adjust to, revealing the manufacturing know-how and a focus to element practiced inside Bulgari’s partitions. A whole bunch, typically as much as a thousand of components should be designed, prototyped, made, checked, embellished, and assembled to make up a motion and energy certainly one of Bulgari’s watches — and it’s this know-how and in-house capacities which have enabled the model to develop, produce, and produce to market eight world-records in watchmaking within the scope of simply 10 years.

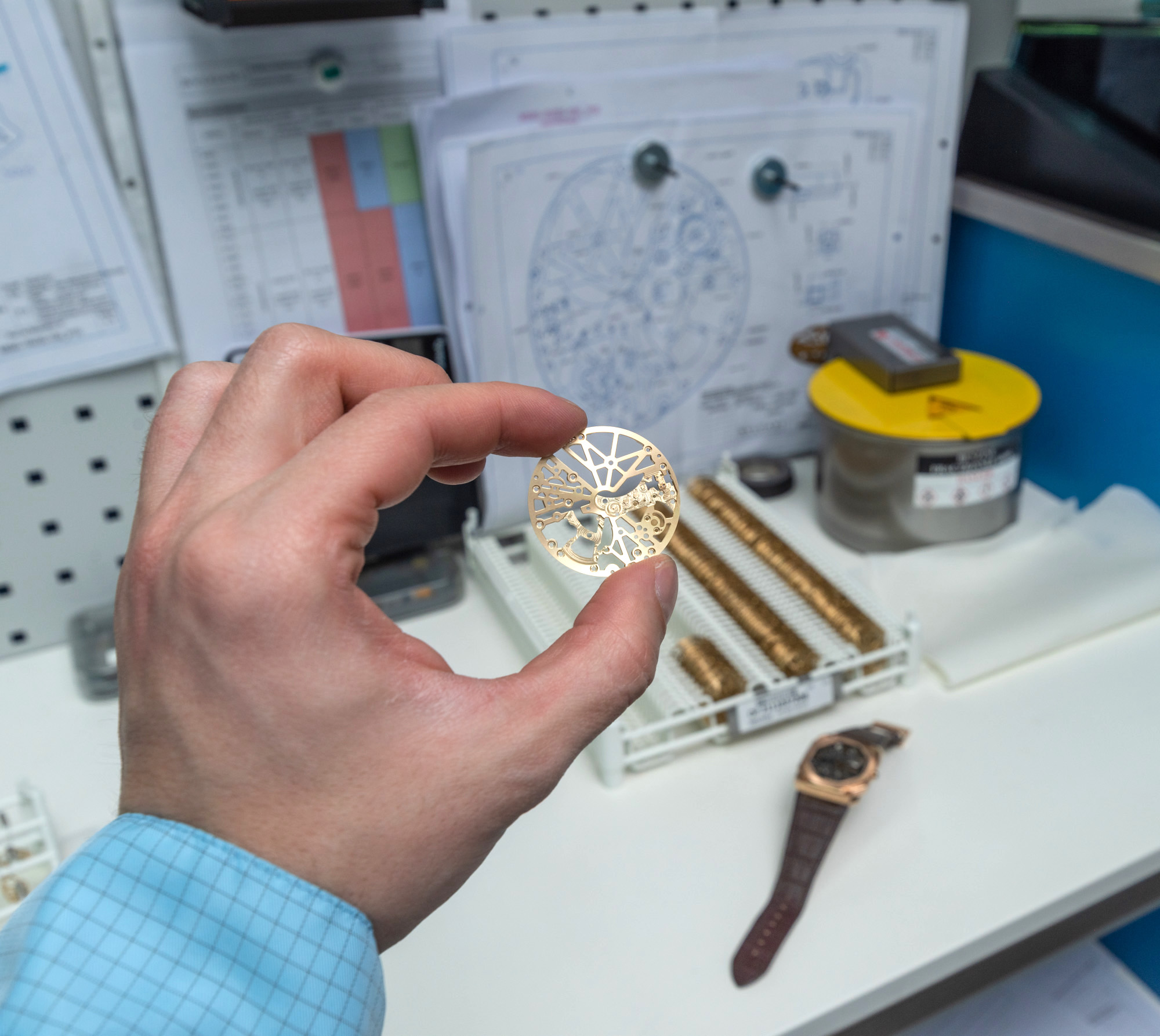

Bigger motion components reminiscent of plates and bridges are additionally developed and produced by Bulgari for its in-house actions, just like the BVL199SK skeletonized, ultra-thin, eight-day energy reserve motion that’s contained in the Octo Finissimo Skeleton 8 Days. Each gap that can match a jewel is crafted with a tolerance of only a few microns, i.e. a number of thousandths of a millimeter, with complicated, three-dimensional shapes, curves, and bridges built-in into the primary plate in pursuit of final thinness. Consequently, the eight-day motion is a surprising 2.5mm-thick, and but gives each little bit of depth and intricacy one would anticipate from a high-end mechanical caliber. Parts are sometimes embellished with hand-applied perlage and hand-beveled edges.

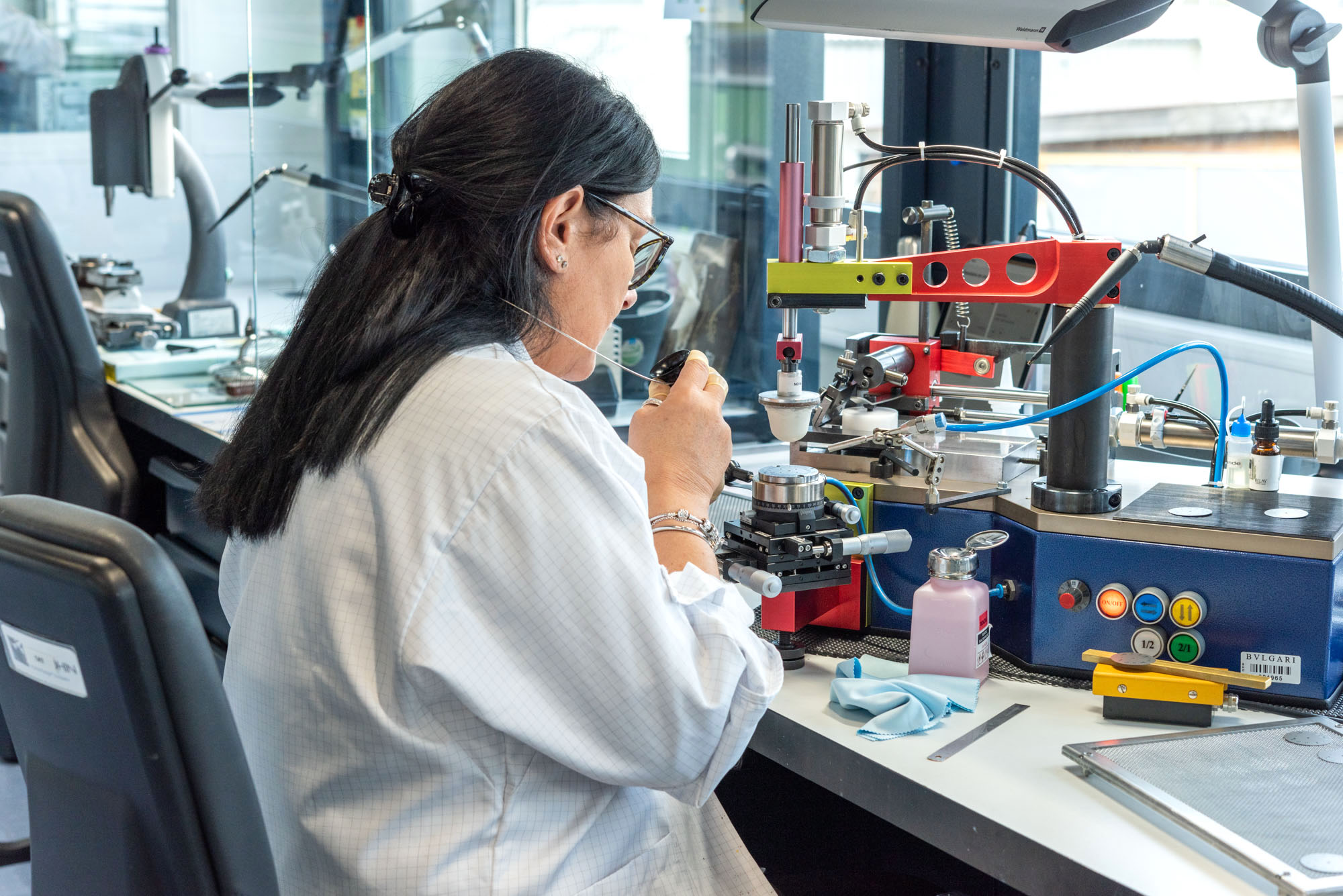

It’s also right here in Le Sentier that Bulgari’s watchmakers fill a big upstairs room, with loads of mild, and carry out pre-assembly and meeting duties on Bulgari actions. Actions with extraordinarily delicate components are very a lot widespread right here, however sure Bulgari creations are inclined to push the boundaries there, too. It’s right here, on this temperature and dust-controlled room that particular dials and “arms” are fitted onto Bulgari’s actions, together with tiny discs with delicate, actual feathers and a diamond, the latter to level out the precise time. The actions should be engineered to offer ample torque to drive these discs that are usually a number of occasions as heavy as filigree watch arms of conventional designs, and the meeting and regulation should additionally occur in accordance with the particular necessities of those distinctive elements. For sure, requesting the alternative of any of those components, ought to something occur, shouldn’t be one thing any watchmaker would need upon themselves, which is why they lean on this absolutely outfitted and devoted surroundings, arrange for the meeting of all Bulgari manufacture calibers.

As its title implies, the Bulgari Manufacture De Haute Horlogerie can be the place the ultra-high-end watch creations of Bulgari are produced, embellished, and assembled. Extremely skeletonized tourbillon actions with ornamental stone hour markers, true grand complication watches with 600-1,000 elements powering refined chiming mechanisms, perpetual calendars, and tourbillons — it’s right here, and solely right here, that they see the sunshine of day. The eagle-eyed are invited to check photographs from this go to and people from 2015 to search out many acquainted faces, among the most highly-trained watchmakers who’ve been honing their abilities and performing their artwork right here, in Le Sentier, at Bulgari’s manufacture all this time.

The three photographs above characterize a fluid movement backward. The small, clear containers are delivered from inside the Bulgari manufacture; every element inside has accomplished its journey from the pc screens of engineers and early bodily prototypes by way of collection manufacturing and numerous high quality management steps to this very room and this very desk. Now it falls on this handful of watchmakers to construct these components into probably the most difficult watches of the model, typically taking as much as six months from starting to completion on sure grand complication fashions.

All however the haute horlogerie items are assembled in Neuchâtel, at Bulgari Horlogerie. It’s right here that the finished, examined, finalized actions, the fantastically completed dials, and the completed circumstances and bracelets are despatched for emboîtage, i.e. casing-up, in addition to the becoming of the straps or bracelet. Water resistance and stress resistance are examined as soon as once more earlier than the watches are given one final, ultimate aesthetic management.

This leads us to the top of our go to with the gallery simply above, displaying only a few of the controlling steps that Bulgari’s craftspeople carry out tons of of occasions each day as a part of their pursuit of uncompromised high quality. It’s protected to say {that a} Bulgari watch, and all its elements, produced inside the partitions of the built-in Bulgari manufacture have been checked tens of 1000’s of occasions alongside the best way. One would anticipate such dedication but it surely actually is one thing particular when utilized in follow.

From design and growth by way of manufacturing and meeting to ultimate high quality management, Bulgari has devoted super effort, power, and sources to take advantage of its built-in watch manufacture. By merging its proprietary case and dial manufacturing amenities it has introduced its individuals nearer collectively, efficiently gathering them across the purpose of chasing record-breaking thinness and all-encompassing high quality of execution, as mirrored in its eight world information and a longtime assortment of extremely inventive watches which are distinctive each in and out. You can learn more at the Bulgari website.

Sponsored Posts are a type of promoting that permits sponsors to share helpful information, messages, and gives to aBlogtoWatch readers in a method conventional show promoting is commonly not greatest suited to. All Sponsored Posts are topic to editorial tips with the intent that they provide readers helpful information, promotions, or tales. The viewpoints and opinions expressed in Sponsored Posts are these of the advertiser and never essentially these of aBlogtoWatch or its writers.

[ad_2]